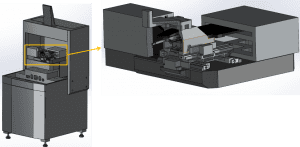

Use case: Digital Twin of Industrial Wire Bonder Machine

Strengthening the competitive edge in the market of the assembly and packaging equipment for electronics manufacturing, digitalization and virtualization is of increasingly importance at ASM Pacific Technology LTD. Especially digital twins of the ASM products are getting particular attention, because of their values in all phases of equipment development, production and operational use.

In this project, we develop digital twins of an industrial wire bonder machine, which makes wired interconnections between the semiconductor die and its packaging. These interconnections are created by rapid machine movements at high speeds and accelerations, with sub-micrometer precision. A digital twin of a wire bonder should capture machine dynamics that have critical influence on accuracy of the machine motions during wire bonding. Furthermore, model updating algorithms will be developed for automated and time-efficient calibration of the model parameters

(e.g. stiffness and damping coefficients). We also aim to incorporate multi-physics models into the digital twin, by modelling thermally induced mechanical deformations of the machine parts that affect precision of the wire bonding.

The resulting digital twin will help us:

- Understand root-causes of the critical machine dynamics

- Compensate for position errors caused by structural and thermal deformations

- Optimize machine design

- On-the-fly machine health monitoring and fault isolation

Industrial Partners

Dr.ir. Dragan Kostić

Dr.ir. Dragan Kostić is the R&D Director for Mechatronics Enabling Technology at the ASM Center of Competency in Beuningen. His professional career incorporates different positions at academia and in industry in the fields of mechatronics, robotics and metrology. Since 2017 he leads R&D activities at the Center of Competency on the problems of digital twin building, simulation, control technology, machine health management, and mechatronics system development.

Dr.ir. Dragan Kostić is the R&D Director for Mechatronics Enabling Technology at the ASM Center of Competency in Beuningen. His professional career incorporates different positions at academia and in industry in the fields of mechatronics, robotics and metrology. Since 2017 he leads R&D activities at the Center of Competency on the problems of digital twin building, simulation, control technology, machine health management, and mechatronics system development.

Dr. Ben van der Zon

Dr. Ben van der Zon obtained his PhD in solid state physics at the State University of Leiden. After R&D and collaboration positions in the defence industry, semiconductor equipment industry, government and at institutes he joined the ASM Center of Competency as consultant for scouting and setting up industrial, academic and institutional innovation collaborations.

Dr. Ben van der Zon obtained his PhD in solid state physics at the State University of Leiden. After R&D and collaboration positions in the defence industry, semiconductor equipment industry, government and at institutes he joined the ASM Center of Competency as consultant for scouting and setting up industrial, academic and institutional innovation collaborations.

ir. Robin van Es

In 2018, Robin van Es received a M.Sc. degree in mechanical engineering (cum laude) from the Eindhoven University of technology, The Netherlands. Since then, he has worked as a mechatronics engineer at the ASM Center of Competency, Beuningen.

In 2018, Robin van Es received a M.Sc. degree in mechanical engineering (cum laude) from the Eindhoven University of technology, The Netherlands. Since then, he has worked as a mechatronics engineer at the ASM Center of Competency, Beuningen.